Precision Magnetics,

Customized to Your Design Needs

Start Your Custom Design

Built Around Your Requirements

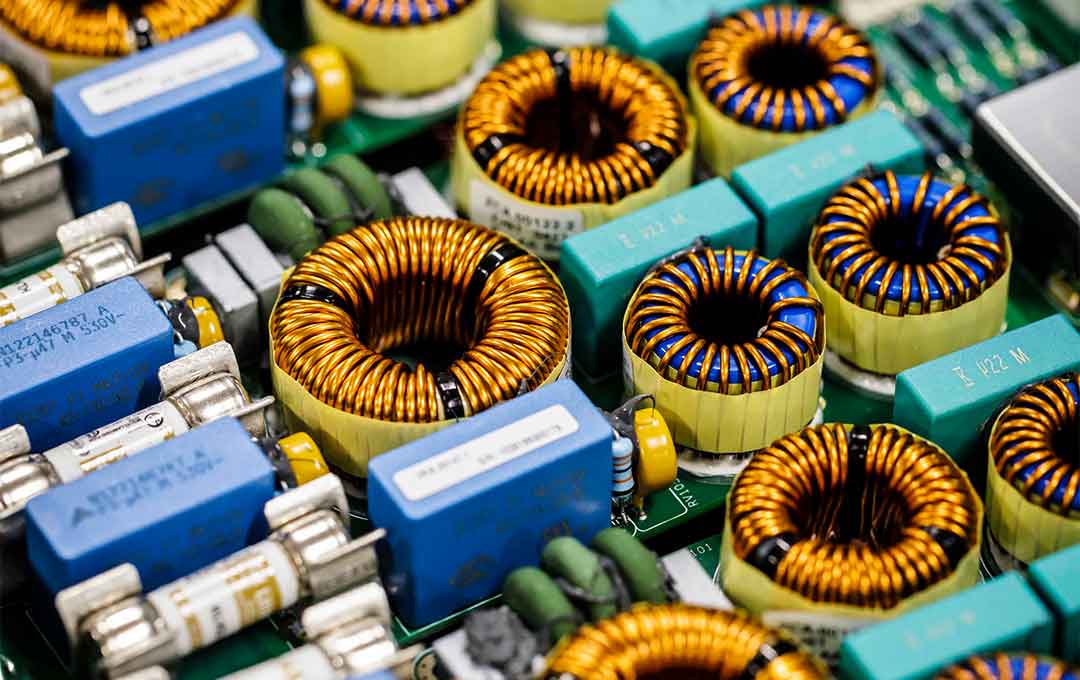

Whether you're working with transformers, inductors, chokes, or coils, the Signal product line offers a wide range of customization options to meet your exact electrical, mechanical, and compliance needs.

Explore the core capabilities below to see how we tailor each component to support your system requirements.

-

Power Rating

Power Rating

-

Frequency Range

Frequency Range

-

System Configurations

System Configurations

-

Safety Certifications

Safety Certifications

-

Core Materials

Core Materials

-

Core Shapes

Core Shapes

-

Custom Laminations

Custom Laminations

-

AC Line

AC Line

-

Common or Differential Mode

Common or Differential Mode

-

Current Limiting

Current Limiting

-

DC Filter

DC Filter

-

DC Link

DC Link

-

DC Swinging

DC Swinging

-

Grounding

Grounding

-

Harmonic Filter

Harmonic Filter

Electrical Modifications

Tailored to improve system performance, our electrical customizations include:

- Impedance matching

- Voltage and current adjustments

- Frequency response optimization

- Thermal management modifications

- Precision tuning for performance and reliability

Mechanical Modifications

Built to support smooth integration and lasting performance, our mechanical customizations include:

- Specialized enclosures and packaging

- Tailored lead wiring and flying leads

- Custom mounting options for secure installation

- A variety of terminal types to meet your connection needs

- Printed circuit mounts for efficient assembly

Industry Standards & Regulations

We manufacture products to meet a wide range of industry certifications, supporting safety, environmental, and quality standards across global markets. Certification availability varies by product line - let us know your requirements.

Safety Certifications

-

UL - Underwriters Laboratories (U.S.)

-

CSA - Canadian Standards Association

-

VDE - Verband der Elektrotechnik Elektronik Informationstechnik (Germany)

-

IEC - International Electrotechnical Commission

Environmental Certifications

-

RoHS - Restriction of Hazardous Substances

-

REACH - Registration, Evaluation, Authorization, and Restriction of Chemicals

Quality Certifications

-

ISO 9001 - Certified Quality Management System

-

IATF 16949 - For automotive industry quality

Reverse Engineering Capabilities

Revitalize your legacy systems with our reverse engineering expertise. We can quickly and cost-effectively recreate discontinued parts or extend the life of your equipment to maintain a competitive edge.

By carefully disassembling and analyzing original products, we can replicate end-of-life components with improved performance through material substitution, compliance updates, and detailed documentation.

Tell Us About Your Custom Magnetic Requirements

Use the form below to contact our sales team and they will assist you with your customization request.

* Indicates requiredRelated Resources