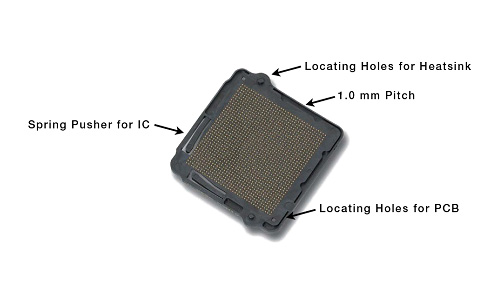

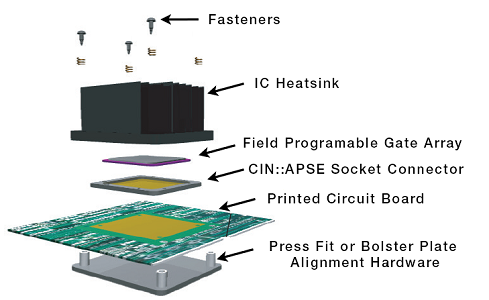

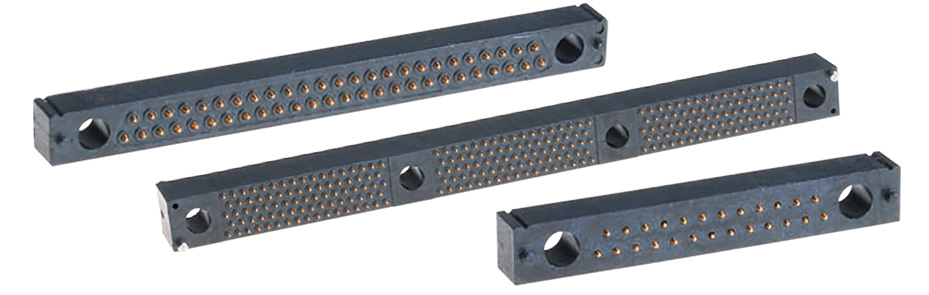

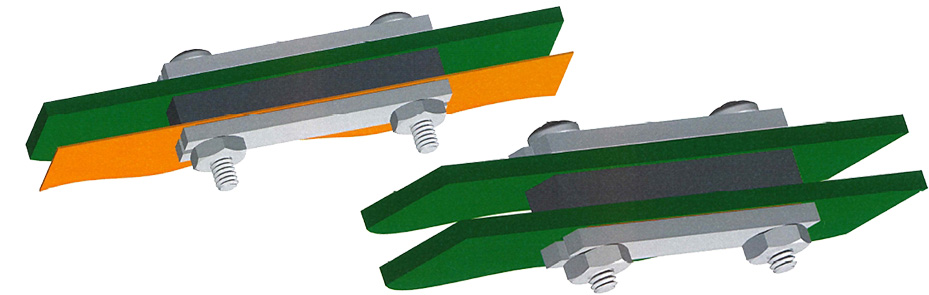

CIN::APSE Connectors

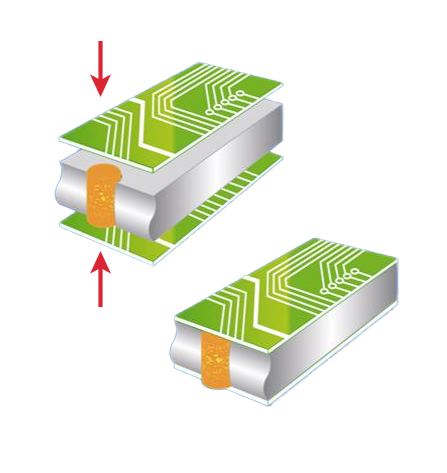

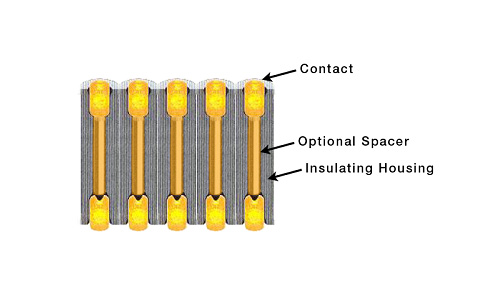

They are constructed of 2 main components, and insulating housing and an electrically conducting contact. The liquid crystal polymer insulators are molded and the contacts are a bundled gold-plated molybdenum wire. Gold plated copper spacers are used for long Z-axis connectors.